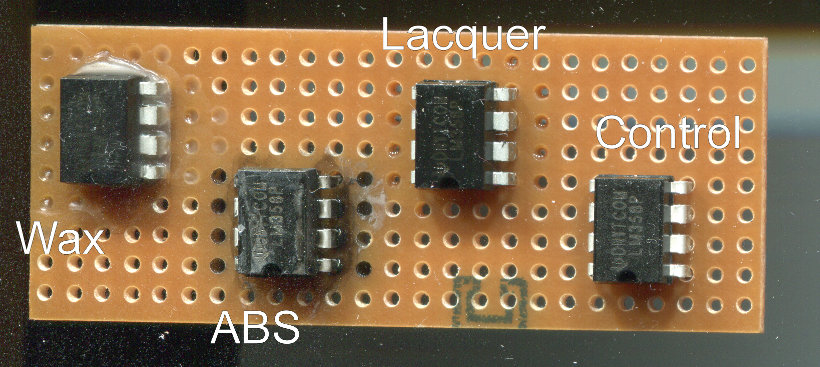

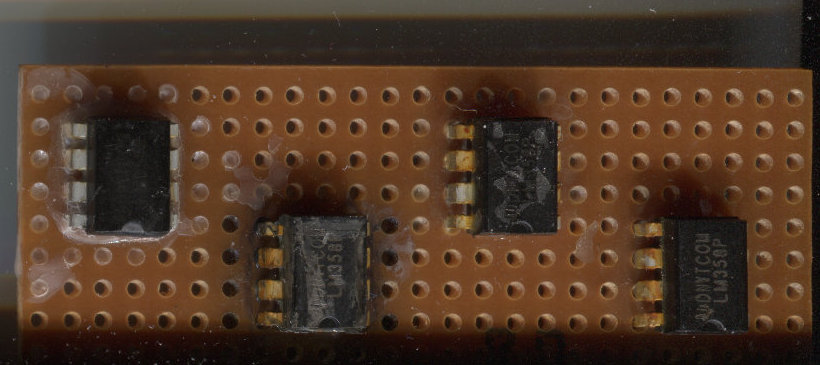

After the failure of an electronics project in my garage due to corrosion, I have conducted a small-scale personal experiment to evaluate possible materials for weather-proofing of stripboard using reading available materials. There are already several commercially-developed products for this purpose, but I have always supported a do-it-yourself idea and so evaluated three materials selected as potentially very-low-cost alternatives for hobby projects. The experiment consists of a stripboard with four identical sample components, three protected and one control.

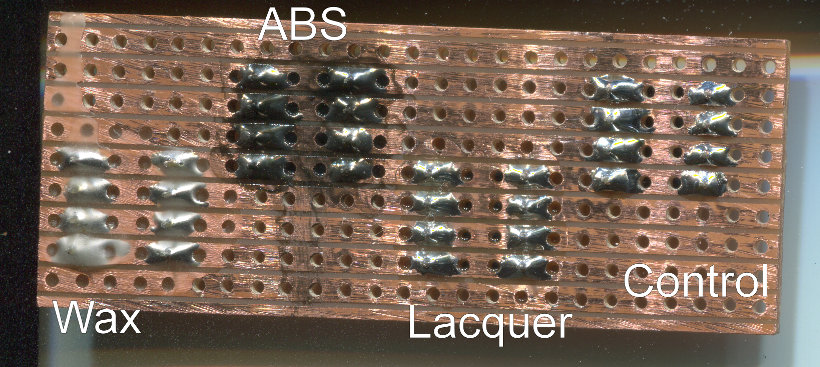

All coatings were given to both sides of the board. The test object was assembled and placed outside for weathering in Kent, UK on December 26th 2016, here identified as Day 0. The location used is an exposed glass-topped table, with a rim that causes the table to be immersed to a depth of 15mm under rain - sufficient to cover the board. These conditions are far more severe than any that a board might be realistically exposed to in order to accelerate the ageing process.

Over the last nineteen days the board has endured direct sunlight, snow, rain, wind-born dust, and even becoming embedded inside a block of solid ice as the depression in which it was sitting was filled with water that subsequently froze. These conditions are far harsher than would typically be encountered by a circuit board in en enclosure, even outdoors.

It is surprising just how poorly the weatherproofing performed. The control is already showing corrosion, and the ABS-coated sample is equally severe. This material has offered no protection at all. The laquer has offered some protection, but has not been entirely effective: It also shows corrosion, to a lesser extent. The wax, however, appears almost unchanged. Though cracks in the wax can be seen, there is no sign of corrosion at all.

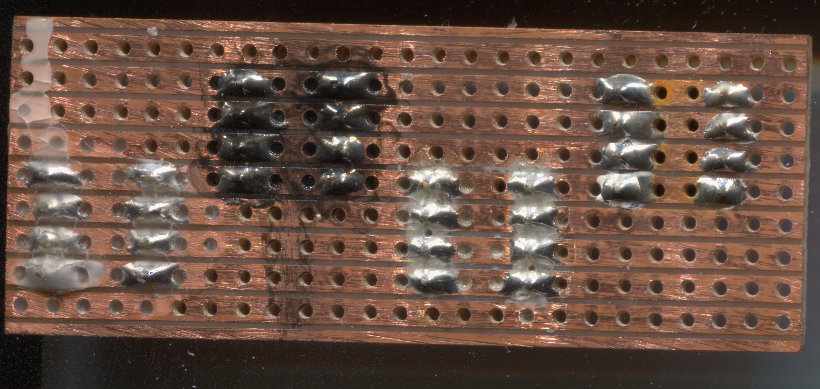

Corrosion of the lower side of the board shows much less damage: The control shows some slight discoloration from corrosion, while the three protected samples are not visibly corroded at all. It is evident that the component legs are far more susceptable to corrosion than either copper or solder.