Observations on PLA plastic and solvents.

This document describes the observations made upon immersing samples of PLA filament into a variety of solvents, conducted with the intention of finding new solvents for use in finishing or production of 3D printed objects.

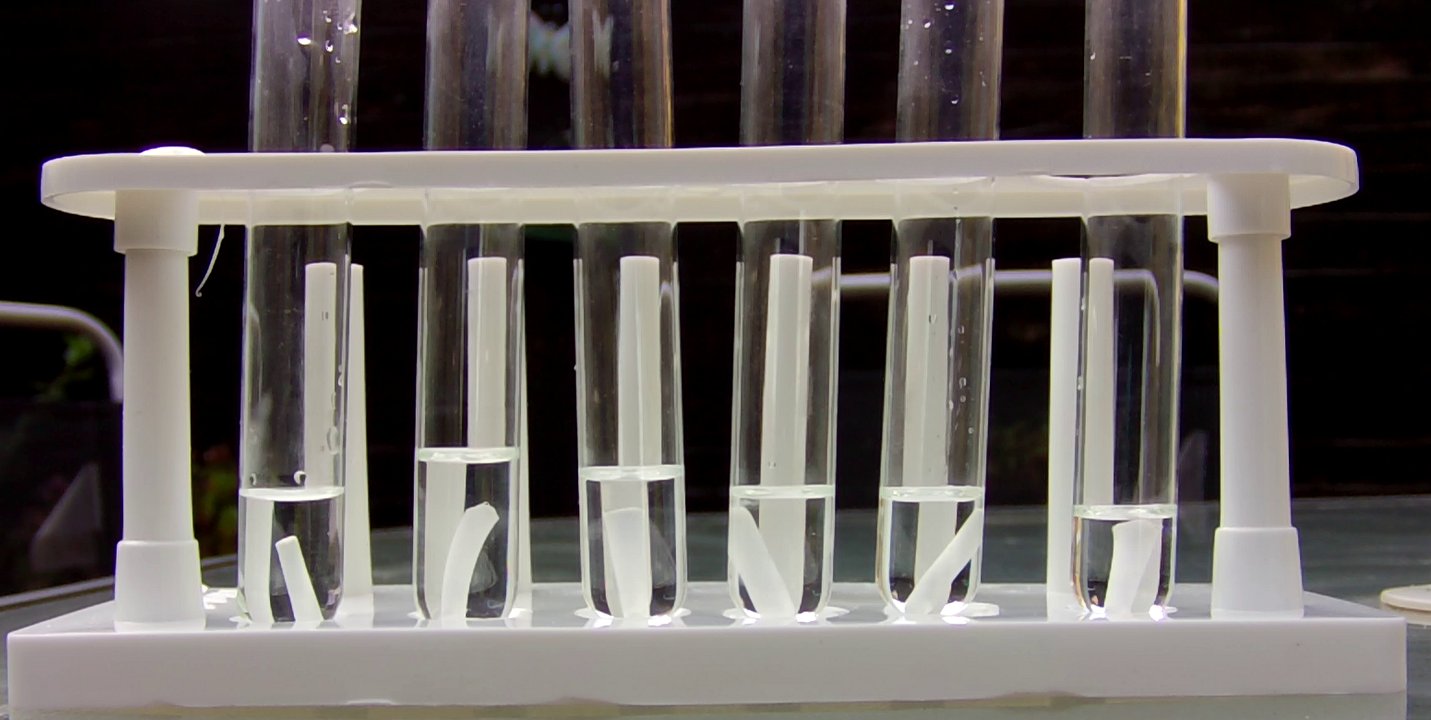

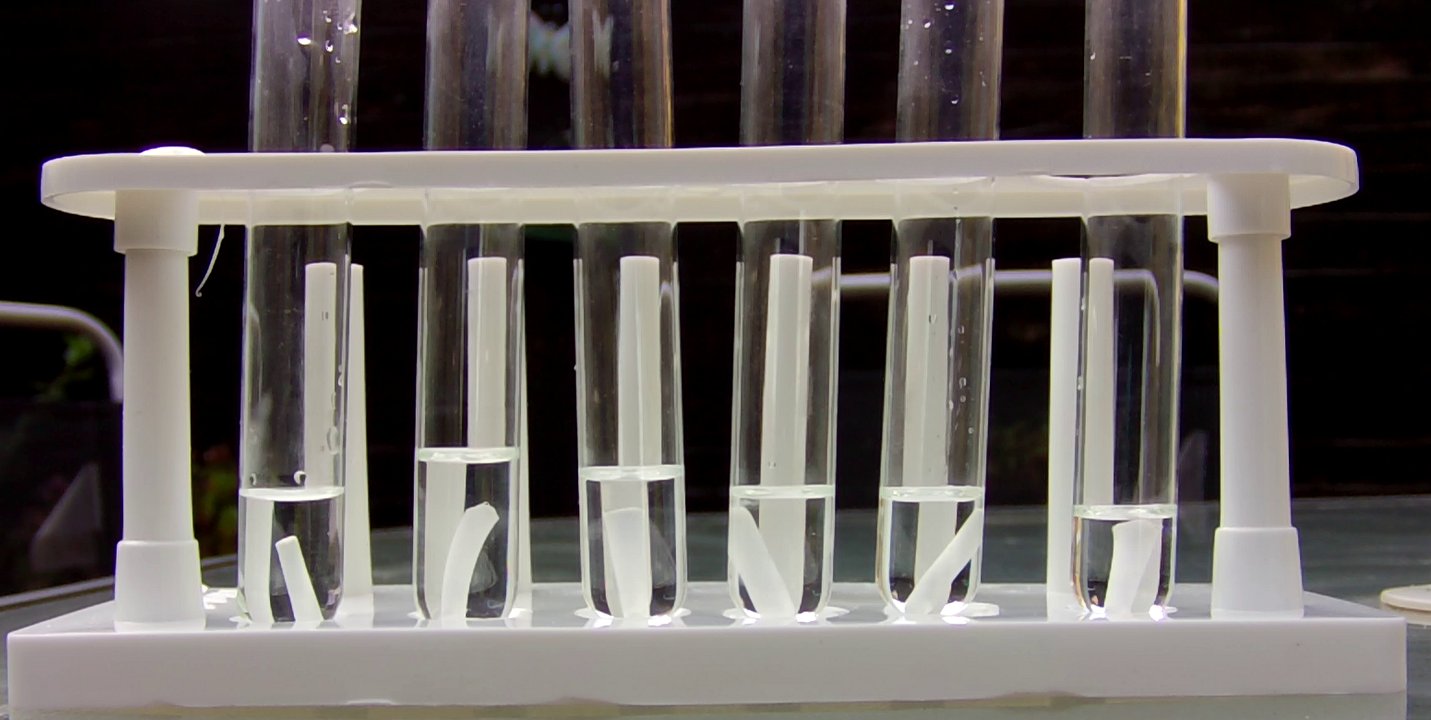

Each sample tested was a 12mm length of 1.5mm diameter white PLA plastic filament as used in 3D printing, purchased from CPC. There may be some differences between manufacturers regarding additives used - 3D printing filaments contain various dyes, stabilisers and plasticisers which may alter their chemistry.

Tests were commenced at 21 degrees celcius. Exact temperature control was not available - this is an amateur study, performed without access to a properly equipped laboratory.

Water

PLA is known to be insoluble in water, but is hygroscopic. The water test was used only to observe any effect resulting from fluid absorbtion. No change in the sample was observed after 1.5 hours of immersion, nor was the diameter altered.

Propanone (Acetone)

Propanone is commonly used for liquid or vapor smoothing of ABS 3D prints. No effect was observed on the PLA example.

Tetrahydrofuran

The PLA does not appear to be soluable, but was altered. The diamater of the filament increased noticeably, eventually leading to lengthwise fracturing of the surface later - though this was a slow process, requiring an hour of immersion before the fractures became visible. This would suggest internal swelling due to the tetrahydrofuran being absorbed into the PLA, rather than acting as a solvent.

Others have reported mixed results with vapor smoothing of PLA using tetrahydrfuran - most notably ProtoParadigm were able to apply it to great success, others report far less. In my own attempt at vapor smoothing, tetrahydrofuran exposure even over twelve hours produced a temporary softening of the print but no smoothing of layers. This contradiction in results may be due to variation in the additives used in the filament.

Dichloromethane

Clouding of the solvent was quickly observed within four minutes, leaving visible strands of white material floating in the solvent. Possibly PLA, or possibly an insoluble addititive. At seven minutes the sample was noticeably greater in diameter, suggesting absorbtion of the solvent.

At ten minutes the solvent was almost opaque. This eventually progressed to the filament sample dissolving completly, leaving only a surface layer of the unidentified white substance.

Upon cleaning the equipment, the dichloromethane solution adhered to the glass leaving behind a thin and irregular coating that proved impossible to remove. This suggests possible application as an adhesive or high-stick coating for the build platform.

Xylene:

No effect was observed on the PLA sample after 1.5 hours of immersion.

Toluene:

No effect was observed on the PLA sample after 1.5 hours of immersion.